Заполните форму

Мы перезвоним Вам в ближайшее время

Нажимая кнопку Вы соглашаетесь с Политикой конфиденциальности

ASPAPTAR ALMATY LLP

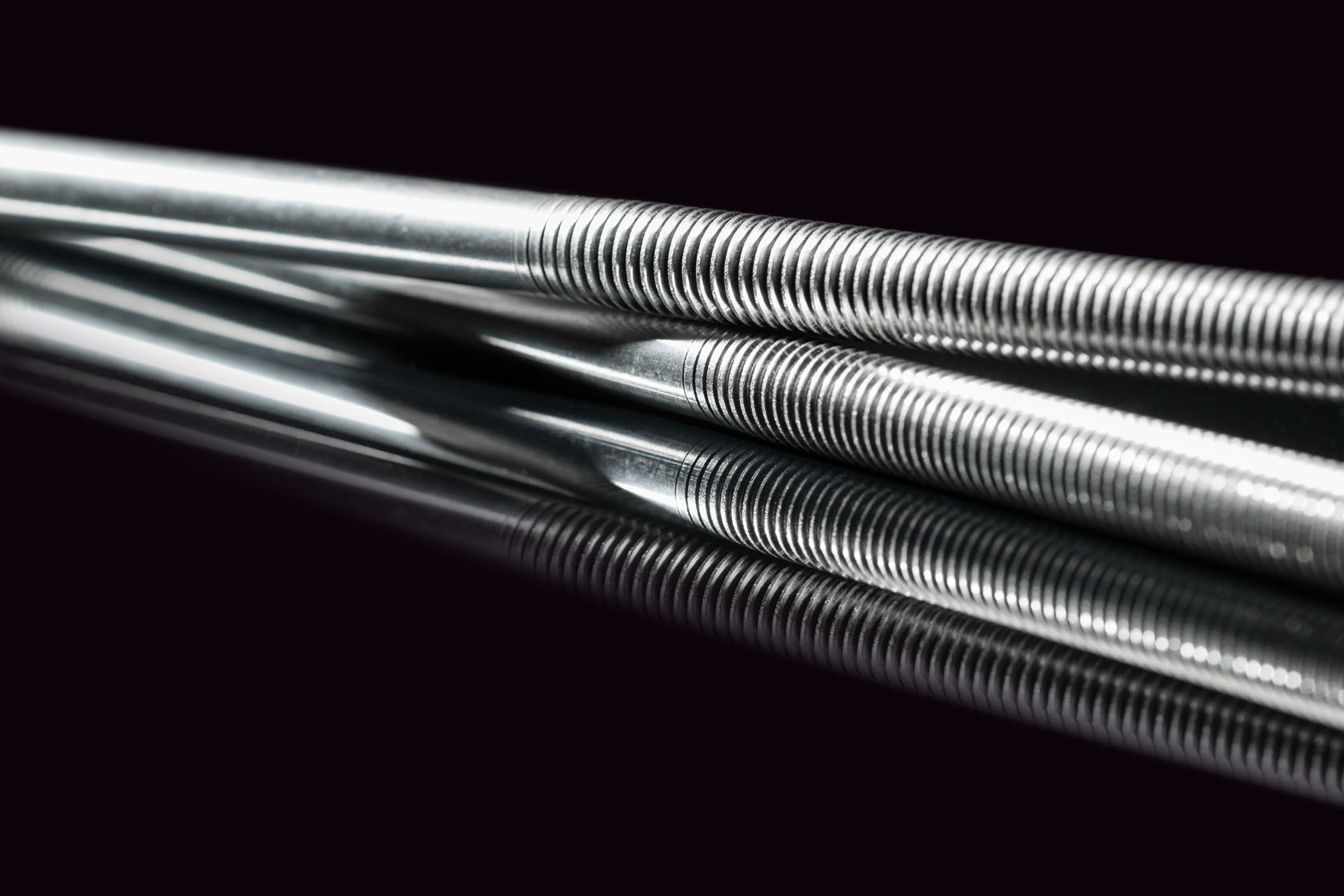

Thread rolling expert

If you produce more than 5,000 threads per month thread rolling is more preferred method because thread rolling has a number of advantages over threading. The main advantage of thread rolling is the speed of thread production. With a thread rolling tool you can use existing equipment, universal or CNC, or you can purchase specialized thread rolling machines.

Advantages

of thread rolling

of thread rolling

Speed

The thread production cycle is from a fraction of a second to several seconds. This allows you to significantly shorten the production cycle, to increase output on the existing equipment and reduce production costs.

Strength

Thread rolling is a plastic deformation process in which the outer layer of the thread is hardened in contrast to the thread obtained with a cutter.

No chips

The thread profile is formed due to the plastic deformation of the metal, which means that there are no chips that need to be removed periodically.

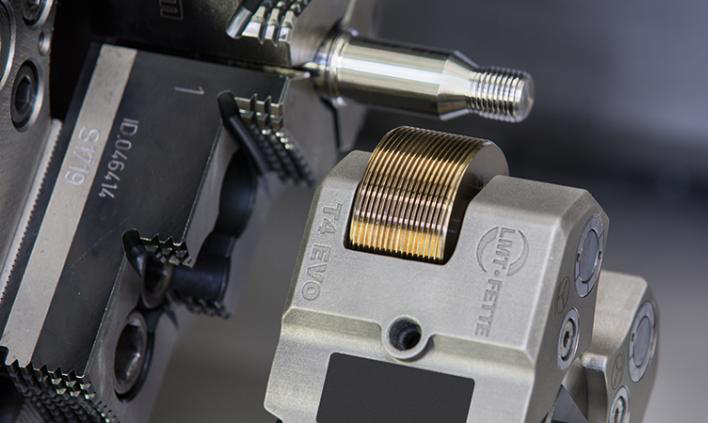

Yes! You can equip any machine with a thread rolling head so you get opportunity to roll threads on the lathe you have.

Yes! In some cases we can offer equipment for the formation of tapered threads on parts by plastic deformation. Most of the time it depends on the angle.

Can!

Thread rolling is possible on almost any steel that matches two requirements: hardness up to HRC50 and relative elongation of at least 5%

Thread rolling heads can be installed on any machine. This is a tool that is attached to a revolver or spindle. You do not need to buy additional equipment, install a knurled head and you will get your own thread rolling machine!

In the case of large-scale production Aspaptar Almaty LLP specialists will help you to choose specialized thread rolling machines.

We cooperate with the machine tool manufacturer “AKEA Automation”, Denmark

We cooperate with the machine tool manufacturer “AKEA Automation”, Denmark

About Us

Popularization of the thread rolling process.

"Full construction" thread rolling - from selection to launch.

"Full construction" thread rolling - from selection to launch.

ASPAPTAR ALMATY LLP

BIN 220340012207

69, Tole Bi Street, office 38/2, Almaty, 050000/A05H1T9, the Republic of Kazakhstan

BIN 220340012207

69, Tole Bi Street, office 38/2, Almaty, 050000/A05H1T9, the Republic of Kazakhstan

Email: info@aspaptar.kz

Phone: +7 (702) 713-44-34

Phone: +7 (702) 713-44-34